Learning & Development

Training

“People need maintenance and upgrades even more than machines do.

Retraining is maintenance. Training is an upgrade. Development is the next generation model.”

If you think education is expensive, try ignorance.

― Derek Bok

Training is the most important aspect in development of human capabilities.

A progressive and sensitive corporates make their Human Resource Department work overtime, by conducting in house surveys, on regular basis to identify gaps in areas of skill development, leadership behavioral, and health and safety aspects.

Technology has its own advantages but the complete exploitation of technology is only possible when human is sensitized, have the requisite skills, talent, thought process, energies and commitments to extract the best out of them and deliver to the expectation of corporates. The best of technologies fails to achieve desired results if the human aspect is not tuned to the level need in terms of their skills and mindsets.

The human assets do not get reflected on either side in the balance sheet but ultimately the results speak volumes about this aspect which is a behind the stage performance which getting reflected in the balance sheet.

Let there be no misinterpretation on this. As we flip through the pages of achieving Corporates and Societies, we find that every page copiously speaks about the sincere, committed, competent courageous & capable manpower that has helped them to thrive the economic sandstorms of time. Today they have become a light house for those who are scrambling for a such space in the world. To decipher this more explicitly:

Technology gives an edge but the cutting edge is provided only by the Human Assets of the Organization.

“Education is the kindling of a flame, not the filling of a vessel as said by Socratus“ It is only TRAINING which pragmatically & properly aligns the EDUCATION creating an EXPERIENCE which is an EVERLASTING asset of the individual. These assets in turn bear fruits for the society, corporates and global community as a whole.

The Programmable Logic Controller is used for automation of processes, machine tools, etc. This when connected to Human Machine Interface, etc. it becomes a powerful tool to control the process and display of critical process parameters.

The course is designed and developed by experienced engineers who have long, varied and rich exposure in the automation domain. The contents, method of teaching, are laced with practical field experience, thereby making it easier for the learning community to deal with the field issues.

The complete course is customized as per International standards. Further the same can be further fine tuned as per the requirement of the participants from industry and institutions.

- Digital Electronics Basics

- Introduction to PLC Family

- PLC Hardware & Architecture

- Input and output cards.

- PLC peripheral component selection and connections.

- Control wiring.

- Source & Sink

- Wiring Different field Devices to PLC

- Basics of PLC Programming software

- Configuring the software.

- Defining and creating applications.

- Addressing inputs and outputs.

- Basic Programming Instructions.

- Advanced programming instructions.

- Uploading and downloading

- Monitoring, Forcing.

- Fault finding and trouble shooting.

- Practicals and hands on experience.

- Customised as per the requirement of Industry and Institution.

- Corporate training module as per requirement.

- Institutional training as per the requirement.

- Weekend training programs.

Human Machine Interface or Man Machine Interface is basically a peripheral device used along with PLC. It has features to provide a high-resolution graphical display of the process with or without animation along with control, data logging and trending facilities.

- Introduction to HMI.

- New applications.

- Tagging and its use.

- Creating and editing screens.

- Communication with PLC.

- Uploading and downloading programs.

- Advantages and disadvantages.

Course duration & prequalification

- Customised as per the requirement of Industry and Institution.

- Corporate training module as per requirement.

- Institutional training as per the requirement.

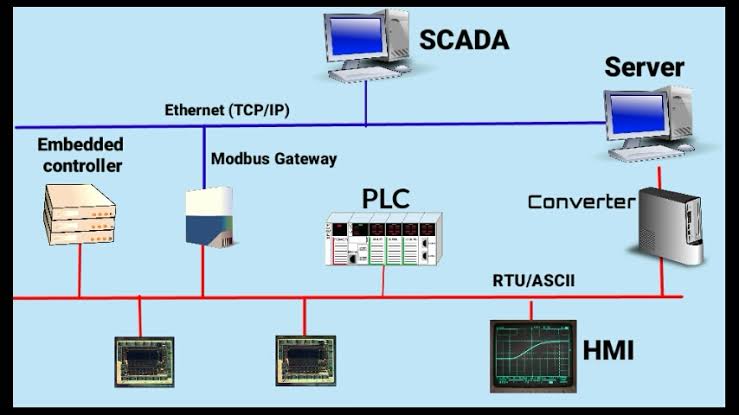

Supervisory Control & Data Acquisition System is an application software which is in direct communication with the PLC. This displays the complete customized animated graphical display of the process plant. In addition, it is possible to control the process as well. In addition to this different logs and trends of various parameters can be viewed, printed with date and time stamp.

Participants are trained on the application of SCADA software, what are the prerequisites for loading on the computer systems. It covers tagging creating various symbols and graphics, animation, Logging, trending & Communication with PLC,

- Introduction

- Creating SCADA project

- Creating Tags

- Creating, editing graphic objects

- Attaching controls to graphic objects

- Animation

- Real time trends

- Alarms & events

- Recipe Management.

- Application of scripts

- Communication with Excel

- Net DDE Communication

- Fault finding / troubleshooting

CONTENTS: Importance of SCADA | Creating new projects | Creating tags | Creating graphical objects | Animation | Trending | Alarms | Recipe Management | Communication with PLC

Who can attend and duration

- Customised as per the requirement of Industry and Institution.

- Corporate training module as per requirement.

- Institutional training as per the requirement.

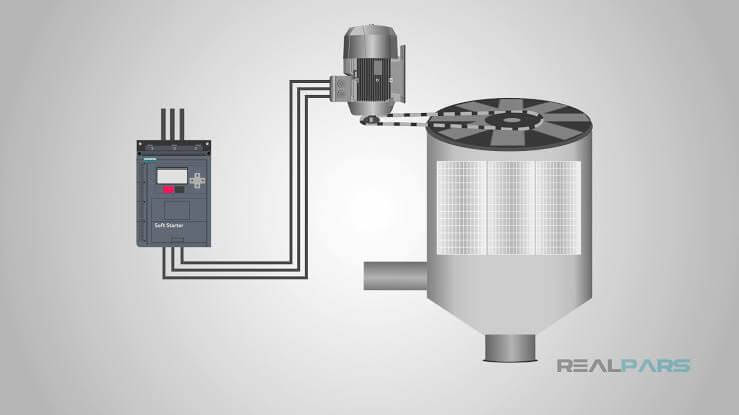

Soft starters is now a leading technology that is being used in the control of starting and running of motors. Since it provides a wide range to starting functions depending on applications , its selections, applications and programming are very critical to meet the requirements.

- Conventional starters for motors.

- Advantages & Disadvantages of conventional starters.

- Softstarters principles.

- Softstarters applications

- Softstarter selection.

- Advantages of softstarters

- Maintenance of softstarter and trouble shooting.

Who can attend and duration

- Customised as per the requirement of Industry and Institution.

- Corporate training module as per requirement.

- Institutional training as per the requirement.

This program is designed for load management of factory, townships and different colonies of the city. Under frequency problem is generated when the load demand increases and utility is not able to manage the load. The system is designed to take care of such eventualities without causing inconvenience to consumers. The system is fully PLC based with ability to self control and manage as per the requirements. This as part of smart control of load management.

- Basics of Loads

- Classification of loads

- Ring and radial feeders

- Conceptual load management requirements

- PLC sizing selection and communication technology

- SCADA requirements

- Skill requirement for such control

Who can attend and duration

- Customised as per the requirement of Industry and Institution.

- Corporate training module as per requirement.

- Institutional training as per the requirement.

Electrical Panels is the nerve centre for any industry in utility. These course is designed who an objective to teach what are the different type of IP protections are there in the panel, what practices need to be followed for maintaining the panels.Importance of earthing and earthing practices that need to be followed. Trouble shooting, safety practices, etc.

- Basics of Loads

- Different type of Switchgears.

- Selection & Coordination criteria for PCC applications

- Selection & Coordination criteria for MCC applications

- Basics of Control & Power Drawings.

- IP Classifications of Panels.

- Electrical faults and their protection.

- Indication and Controls switches

- Metering – Indicating & integrating.

- Norms for Segregation of Control & Power circuits.

- Preparation of Power and Control Circuit.

- Single Line diagram

- Three Line diagram

- Wiring practices and guidelines.

- Trouble shooting & maintenance practices.

Who can attend and duration

- Customised as per the requirement of Industry and Institution.

- Corporate training module as per requirement.

- Institutional training as per the requirement.

Low Tension switchgears are the most common devices that are used in any industry. The objective is to bring awareness with respect to selection and coordination for protections of motors and distribution feeders. The precautions to be taken, for Maintenance Upkeeping & Upgrading their knowledge by educating them on the new trends in technologies that has come in the switchgears.

- Introduction to switchgears

- Classifications with respect to votlages and devices

- Understanding Discrete components

- Power Contactors,

- Vacuum Contactors,

- Overload relays,

- Solid state relays

- Switches

- Switchfuse units

- HRC Fuse links - classifications and selection

- Miniature Circuit

- Breakers

- Moulded Case Circuit Breakers

- Motor Protection Circuit Breakers

- Air Circuit Breakers

- Selection & coordination of switchgear for Motor & Distribution applications.

Who can attend and duration

- Customised as per the requirement of Industry and Institution.

- Corporate training module as per requirement.

- Institutional training as per the requirement.

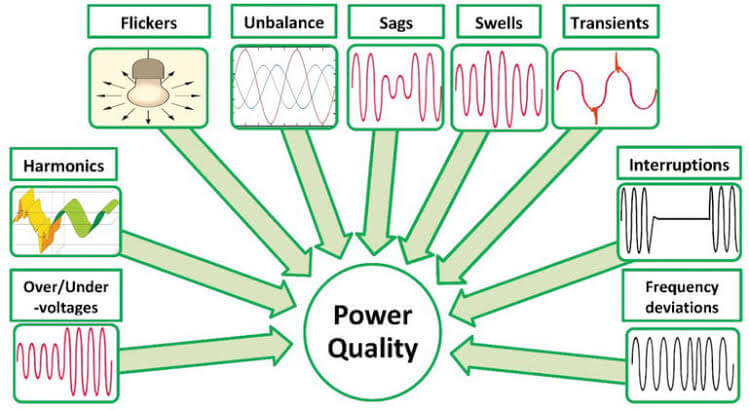

Harmonics are generated in the present time because of use of non linear loads across the plant. Objective is to understand how are they generated, what damage they cause and how they can be mitigated and brought within defined limits.

- What are Harmonics.

- Causes of generation of Harmonics

- Problems caused by Harmonics in supply system

- Identifications of Harmonics in supply systems

- Defining levels in harmonics

- Elimination of Harmonics

- Methods and practices.

- Latest Practices in harmonic controls

Who can attend and duration

- Customised as per the requirement of Industry and Institution.

- Corporate training module as per requirement provided where possible.

- Institutional training as per the requirement.

Power factor correction and control is important aspect in any industry. Where compensation of power should be carried out in the plant in order to reap maximum benefit of the correction. What is the effect of harmonics in the capacitors and how bank can be protected.

- What is Power factor

- What is reactive, active and apparent Power

- Impact of Poor Power factor on Billing

- Methods for improving Power factors

- Modern Power factor relays features and advantages Their selection and applications

- Capacitors selection

- Steps to be used in capacitors

- Limitation of Capacitor type of compensation.

- Other methods of compensation and their applications

Who can attend and duration

- Customised as per the requirement of Industry and Institution.

- Corporate training module as per requirement.

- Institutional training as per the requirement.

Applications of motors are varied. Hence the protection of the motors are to be designed with respect to the motor and applications. They are many solutions for protection of motors. Customizaton of the protection has to be carried out to ensure optimum protection to motor and application.

- Introduction to Induction Motors.

- Different type of Motor starters

- Present trends in Motor protection.

- Different combinations of starters

- Selection of Motor protections systems as per applications

Who can attend and duration

- Customised as per the requirement of Industry and Institution.

- Corporate training module as per requirement.

- Institutional training as per the requirement.

This program is designed for Electrical Maintenance Engineers , Supervisors & Workers. Transformers are a major and critical installation in a utility of industry. They need to be properly erected, installed commissioned and maintained during their life time for delivering uninterrupted power during its life time.

Motors are the major loads in any industry. Their operations are critical to operation of the plant. Any breakdown can result in losses and since they are different rating exact replaments are sometimes are problem. Their installation, regular mechanical and electrical maintenance and protection practices need to be followed for getting un interrupted performance from them.

- Key design aspects of transformer

- Different Major components of Transformer

- Winding configuration and its importance

- Test s/Pre-checks to be conducted after unloading

- Storage of transformer at site.

- Installation & Erection at site.

- Pre commissioning tests

- Dissolved gas analysis , etc.

Who can attend and duration

- Customised as per the requirement of Industry and Institution.

- Corporate training module as per requirement.

- Institutional training as per the requirement.

This program is designed for Ulitities, Large Industrial complexes,, Like Fertiizer plants, Oil complexes, etc. Where special maintenance skills are required for maintenance of the Transformers.

- Precautions to be taken during transportation

- Key design aspects of transformer

- Different Major components of Transformer

- Winding configuration and its importance

- Unloading practices & Precaution at site.

- Test s/Pre-checks to be conducted after unloading

- Storage of transformer at site.

- Precautions to be taken

- Installation & Erection at site.

- Cooling system installation

- Pre commissioning tests

- Dissolved gas analysis , etc.

Who can attend and duration

- Customised as per the requirement of Industry and Institution.

- Corporate training module as per requirement.

- Institutional training as per the requirement.

Solar power is the most promising field that his develop in the time to come. The roof top and utility level generation will be playing a major role in shaping the power sector in the time. This shall tremendously reduce the pressure on conventional generating capacities along with power independence. The workshop is designed to express the importance of solar power, technology used and its advantages.

- What is solar power

- Photo voltaic cell

- International norms which are emerging and shaping the energy scenario

- Different types of method for power generation

- Solar inverters basic

- Micro inverters

- String Inverters

- Central Inverters

- Technnology for communication

- Maintenance

Who can attend and duration

- Customised as per the requirement of Industry and Institution.

- Corporate training module as per requirement.

- Institutional training as per the requirement.

Energy being one of the expensive inputs. Need to be watched carefully. Small saving result in large cumulative savings. Methods of measurement adopted for measurement of energy and how total plant integration helps in saving the energy and the cost.

- What is energy Management systems

- Environmental and Economic benefits.

- ISO50001 and its importance.

- Implementation of Energy Management in organization.

- Field implementation of Energy Management systems.

- Cost benefit analysis in implementation.

- what are the different technologies in the market.

- Cost economics for selection of different type of meters at various locations

- PLC based energy management system for load management in the plant.

- SCADA & DAS

Who can attend and duration

Maintenance & Engineering |Utilities | Design & Engineering

- Customised as per the requirement of Industry and Institution.

- Corporate training module as per requirement.

- Institutional training as per the requirement.

Substation automation has acquired a major importance. The substation is basically a link between the Large receiving station and distribution centers. It has become vital in distribution of power, localization of faults, information pertaining to future requirements.

These can be described as ’artifacts of the eighties’ - the time in which many of them were developed. The communication protocols of these legacy standards were developed for serial link technology and were later adapted to run over TCP/IP-Ethernet. From the start, one of the objectives of the legacy protocols was to account for bandwidth limitations by minimizing the number of bytes sent. Many of these protocols were proprietary and thus communication between devices from different vendors were generally not possible.

The objective of this program is to train Substation Maintenance staff with practices to be followed for maintenance of substation. The substation comprises of different items like Isolators, Breakers, Current Transformers, Potential Transformers, Power transformers, Grounding switches, Relay & protection panels, Earthing practices, etc. This shall include preventive Maintenance Practices, Safety practices to be followed during Maintenance.

- Why substation Maintenance is required?

- What all items substation has.

- Control & Relay Panels

- Battery and battery charger

- Tap changer panels

- Indoor and out door Breakers, OCB, VCB. SF6 Circuit Breakers.

- Isolators

- Earth switches.

- Lightening arrestors.

- CT & PT

- Transformer

- Earthing & Earthing system nuance

- Safety Practices.

Who can attend and duration

Maintenance & Engineering |Utilities | Design & Engineering

- Customised as per the requirement of Industry and Institution.

The primary role of the SAS is to provide safe, secure, and reliable local/remote control and monitoring of high-voltage AC distribution and transmission stations. The Substation Automation System has shifted from the earlier RTU & PLC based to system architecture as per IES-61850. The utility requires a multi-layer redundant control system using protection Intelligent Devices - (IEDs) from diffrent manufacturers.

The IEC 61850 standard is internationally adopted for its interoperability, extendibility, enhanced performance and flexibility, and reduced wiring costs. All of these benefits will ultimately reduce engineering design costs. and improve engineering and maintainability

The course is designed suitably to address the participants to understand about, IEDs, Protocols, IES61850 requirements and norms. Bay Control unit etc. The course contents are elaborately mentioned in the Contents section.

- Customised as per the requirement of utility, Industry and Institution.

- Instituional training as per the requirement.

Who can attend and duration

- Customised as per the requirement of Industry and Institution.

- Corporate training module with hands on learning.

- Institutional training as per the requirement.

Overhead crane form the basic part of any large engineering and manufacturing industry. Infact they form the backbone for material handling specifically for handling large loads during shifting, assembling, loading, testing, etc. This course is specifically designed for the Engineering & Maintenance staff who are responsible for maintaining, running and safety fo equipment and persons using these assets.

- Different types of cranes in industry other then mobile crane.

- Major components of the crane.

- Lifting D shackles

- Lifting Slings Steel

- Lifting hooks

- Lifting Sling – Fibres

- Lifting Load Analysis.

- Hoisting & Rigging Practices.

- Roles & responsibilities of Signal man.

- Overhead crane operation.

Who can attend and duration

- Customised as per the requirement of Industry and Institution.

- Corporate training module with hands on learning.

- Institutional training as per the requirement.

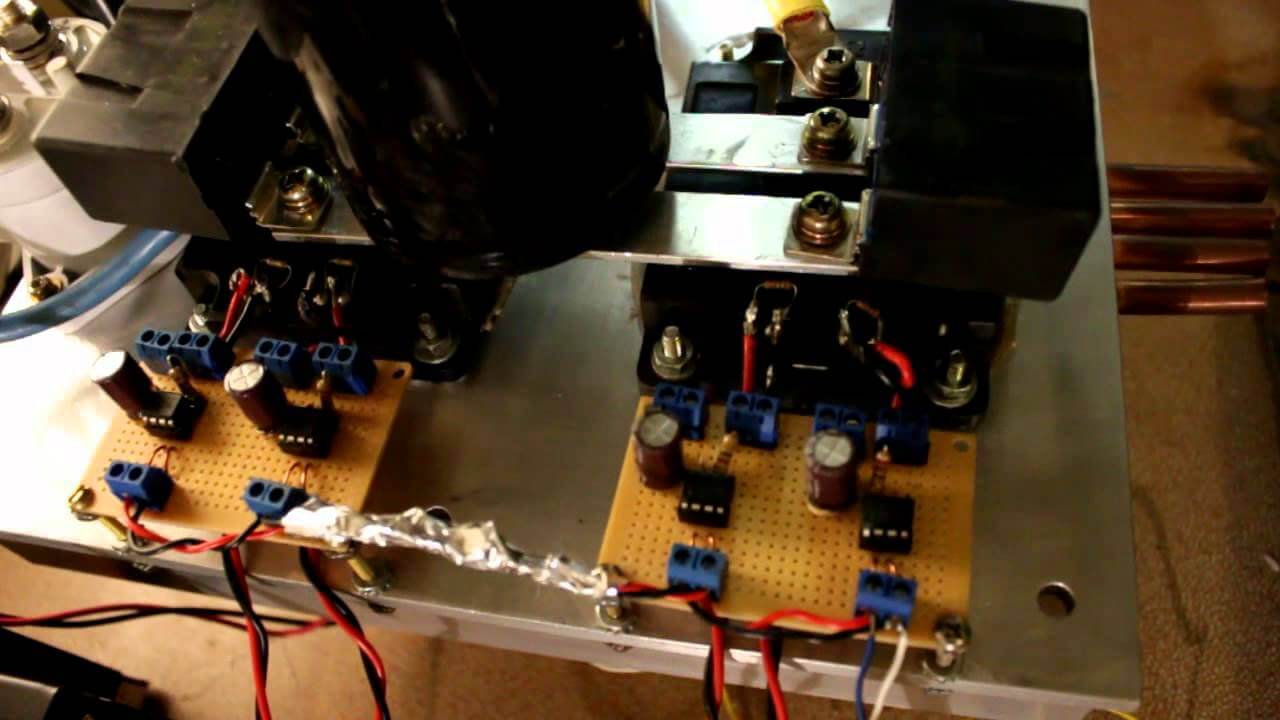

This program is designed with an objective to provide a complete training in motor basics and how to use drives for AC/DC motors for various applications. Since drive is a vide spectrum application product it is important to know how the same can be programmed for different applications. What are the criterias for selection of drives, How to trouble shoot the product and maintain them.

- AC motors, operations & Limitations

- Motor Efficiency as per Intenational Standards.

- Sizing of AC induction Motors for various applications.

- Calculation of Efficiency of Motors in Field applications.

- Criteria for replacement of Motors.

- Motor Starters : DOL, Star-Delta, Auto Transformer

- Motor control circuits, interlocking circuits

- Introduction to AC drives & applications

- Criteria for drives selection

- Parameter Programming

- Finding Fault & trouble shooting.

- Designing of drive control panel

- Communication with PLC, SCADA Software

- Fault finding / troubleshooting

Who can attend and duration

- Customised as per the requirement of Industry and Institution.

- Corporate training module with hands on learning.

- Institutional training as per the requirement.