Industrial Internet of Things

Automation Consultants can give your software development and IT operations a competitive edge. We deploy the latest automated products and techniques with an emphasis on quality and deep expertise.

Automation today is no more a fashion talk but it has become a necessity and reality of time. With globalization and evolution of newer concepts of manufacturing the solutions have moved from humanskill domain to machine centric automation. Further the twins of present time, Information Technology (IT) & Shop floor side call as Operational Technology (OT) has been bridged, resulting in maturing the manufacturing to a level of optimum utilisation of all assets. The transparency between the shop floor and top floor reaches to a new level.

The industrial communication – the digital thread has helped in interconnecting what were island of activities and information. This has help achieve full process transparency thereby giving instant access to stock levels and reducing reaction time to changing demands. This can also include, like instant access to service team, quick changes to product demand and real time global data availability.

This not only takes care of production but covers the entire gamut like process, loading of machines, preventive maintenance and Breakdowns work and shift, owner output, security, scheduling, quality etc. It is the automation that holds the keys to increased asset utilisation, delivering output at low cost and and increased profit. Sooner or later the organisation need to fall in to keep pace with the globe.

Food & Beverages

Packaged and processed food is taking a new face with this rapid industrialization. This requires a very reliable, flexible and precise automation technology to meet the standards of processing and packing. The same assets can be effectively be utilized for manufacture of different products. we provide consultancy in.

- Tank farm automation.

- Sterilizer automation.

- Autoclave automation

- Panning applications.

- Cleaning in Process Applications.

- Bottling Plant automation.

- Labelling Machine automation.

- Batch Process Applications.

- Recipe Management.

- SCADA system for chocolate/candy plant.

Metal - Mining - Cement

This industry has one of the most harsh operating environment The complete denominator for this is the reliable automation system with SCADA which along with the above requirement will also sustain quality and productivity to national and International standards. Some of the area of automation are;

- Stacker re-claimers.

- Coal handling plants.

- Silo storage systems.

- Refractory brick machines.

- Intelligent/Conventional - Motor Control Centres

- Intelligent/Conventional - Power Control Centres

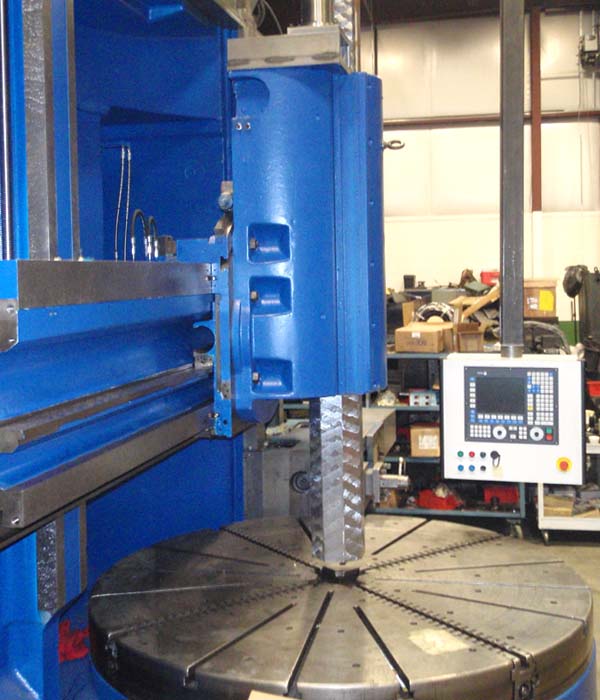

Retro fitting of Machine tools & Plants

Machine tools which are reconditioned and have good mechanical accuracy can be retrofitted. They can be fitted with latest controls like, servos, encoders, PLC, Linear scales and HMI giving them a new lease of life and drastically improves in terms of productivity and accuracy. The cost of renovation and retrofitting is much less thereby saving on the capital investments required on new machines.

- Homa 8 Meter bed Boring Machine.

- Flute Rolling Machine For Transformer radiators.

- German Refractory brick making Machine.

- Georg German CRGOSS Sheet cutting Machine,

- Georg conductor cutting Machine.

- Capacitor film winding machine.

- Transformer winding Machine

- Vertical Boring Machine.

Process Plant Automation

Process plant automation hold the key to quality, productivity and optimum performance. Especially in life science and Pharma industries, where drugs are made for human consumption the process need to be monitored for major and critical parameters. The selection of automation equipment, sensors, transmitter, network are importatant factors for determining uninterrupted performance. Some of the areas application are;

- Autoclaves

- Incubators.

- Chillers and compressors.

- Compactors.

- Bulk drug process plant

- Formulations

- Turbine bypass system

- Over head hoist automation

- Bottling Plant automation

- Seven tank painting process plant.

- Silo storage systems

- Tank farm Automation

- Gas fired ovens for automotive plant.

- Electrically heated ovens

- Stacker reclaimer for cement plant.

- Vacuum Pressure Impregnation plant for Power Transformer Industry.

- Hot Metal forging Press.

Energy Management System

The ISO 50001 Energy Management Systems Standard is an internationally recognized voluntary standard that gives organizations a structured framework to manage energy.

Organizations that have implemented ISO 50001 have reduced energy costs and increased competitiveness while minimizing greenhouse gas (GHG) emissions and other environmental impacts.

Conduct study and energy audit for Power Quality, Efficiency and Consumption. On the basis os study onducted, type of system to be implemented for a particular location is identified. Suitable recommendations are made for adoption of technology for theEnMS system, maintaining power quality and improving energy efficiency.

Utility Automation

Captive Power plants, Compressor air systems, Chillers are important utilities for an process plant and industry. The availability has to be 24X7. For proper performance a complete utility monitoring and maintenance data is required. This is done using PLC system. The consumption data, performance, maintenance requirement, alarms and annunciation both at local and remote locations are key to optimum performance. Some of the key areas are;

- Compressor automation and scheduling.

- DG set synchronization & its SCADA.

- Chillers & SCADA with energy monitoring.

- Automatic Power factor correction.

- Harmonic filters.

- SCADA for Hydro Power Plants.

- Control and relay panels fo utilities.

- Quality Power and Harmonics.

Solar Power Plant Automation

The Solar power plants being installed across the globe. The complete automation & SCADA shall be as per the national standards. Further the technology to be used should be able to provide sustainability for the life of the plant which is approximately 25 years.

- Designing of system

- Engineering

- Supervision of erection and commissioning of system

- Development of SCADA systems as per the requirement of the customers.

- Providing connectivity to Grid as per the National norms and as per IEC61850.

Wind Turbines

The renewable energy sector is a major focus in order to save the environment.

The controls for the wind turbine is highly sophisticated due to the nature of application.

The controls & SCADA system need to have a minimum reaction time in order to provided optimum generation.

Sewage Treatment Plant

Sewage water contains mainly organic waste and some inorganic waste It is important to treat the swage water before it enters any other waterbody. If allowed to do so it will result in contamination of them.Today the complete focus is on sustainable technology which is cost effective. The system is fully automated for reasons of improving the reliability, ease of maintenance, longevity, operation and accuracy.

The consumption of water is almost all sectors, like, Industrial, Residential, Hospitals, hotels, IT Companies, etc. All such application require a precise control over the discharged quality of water and cost effective automation solutions.

We provide consultancy for the electrification, automation & SCADA system for

- Design & Engineering.

- Execution.

- Erection & Commissioning.

IIOT Application.

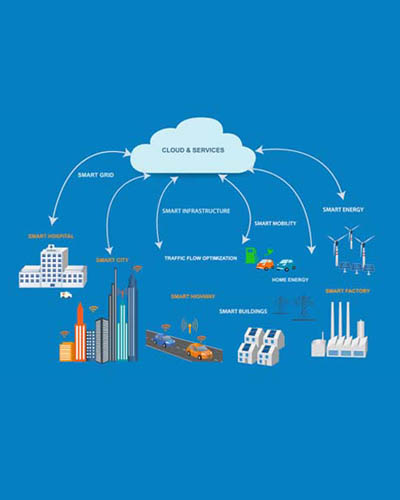

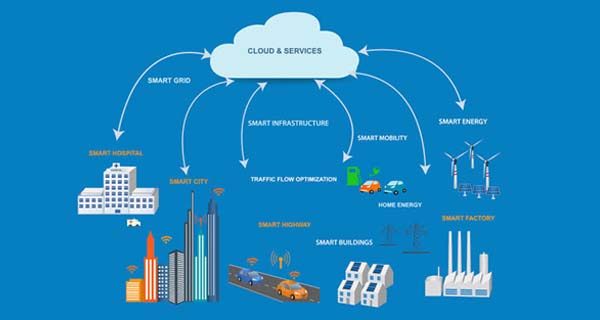

TThis is a the fourth industrial revolution that has commenced with the advent of IIOT. The integration of the TWINS Information Technology & Operation Technology are key to this revolution. With a more secured network technology the IT & OT divide has been bridged bringing every aspect of the production in shop floor to the top floor of the organisation.

We provide consultancy for various applications like, Energy, Factory Shop floor, warehouses, Water treatment plants, Sewage Treatment plants, etc. Each and every details of the plant with respect to productions, breakdowns, Manpower, Efficiency, etc can be provided at a centralised location on a single software.

This dramatically improves visibility, transparency and availability of data on realtime basis for remotely located sites and applications.

Our Clients